Additive manufacturing of collagen scaffolds by three-dimensional plotting of highly viscous dispersions.

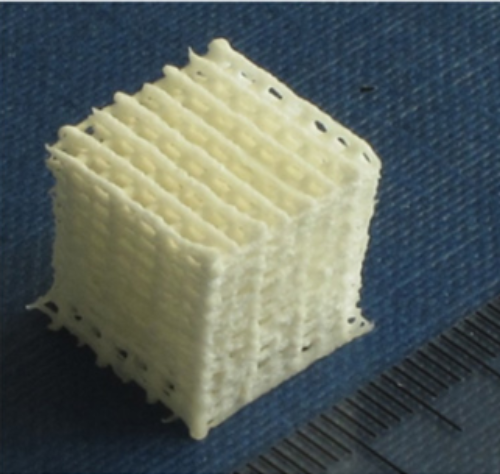

Additive manufacturing (AM) allows the free form fabrication of three-dimensional (3D) structures with distinct external geometry, fitting into a patient-specific defect, and defined internal pore architecture. However, fabrication of predesigned collagen scaffolds using AM-based technologies is challenging due to the low viscosity of collagen solutions, gels or dispersions commonly used for scaffold preparation. In the present study, we have developed a straightforward method which is based on 3D plotting of a highly viscous, high density collagen dispersion. The swollen state of the collagen fibrils at pH 4 enabled the homogenous extrusion of the material, the deposition of uniform strands and finally the construction of 3D scaffolds. Stabilization of the plotted structures was achieved by freeze-drying and chemical crosslinking with the carbodiimide EDC. The scaffolds exhibited high shape and dimensional fidelity and a hierarchical porosity consisting of macropores generated by strand deposition as well as an interconnected microporosity within the strands as result of the freeze-drying process. Cultivation of human mesenchymal stromal cells on the scaffolds, with and without adipogenic or osteogenic stimulation, revealed their cytocompatibility and potential applicability for adipose and bone tissue engineering.

- Biofabrication. 2016 Feb 27;8(1):015015

- 2016

- Medical Biology

- 26924825

- PubMed

Enabled by: